Biodegradable materials for medical applications

Cellulose film, a thin, transparent film made from regenerated cellulose, has gained prominence in medical applications due to its unique properties: biodegradability, breathability, and chemical inertness. Initially developed for packaging, its non-toxic and sterile characteristics have made it indispensable in healthcare settings.

This article briefly introduces critical roles in medical device packaging, drug delivery, and wound care.

1. Material Advantages

- Natural cellulose films, derived primarily from wood pulp (50-60% market share) and agricultural byproducts (e.g., cotton linters, bamboo), offer unique properties for medical packaging.

- Barrier Performance: 90%+ microbial filtration efficiency (MFE) in PPE, Oxygen transmission rate (OTR) <10 cc/m²/day and water vapor transmission rate (WVTR) <20 g/m²/day, comparable to synthetic polymers in dry conditions.

- Biocompatibility: ISO 10993-certified for direct contact with sterile devices and pharmaceuticals.

- Sustainability: 6-month soil degradation, aligning with WHO’s 2025 green hospital guidelines.100% biodegradable under industrial composting (EN 13432) with carbon footprint 60-70% lower than PET alternatives.

2. Dominant Medical Applications

2.1 Sustainable Medical Packaging

- Sterilization Compatibility: Withstands gamma irradiation and ethylene oxide, making it suitable for packaging syringes and implants.

- Eco-Friendly Alternative: Biodegrades faster than conventional plastics, aligning with hospital waste reduction goals.

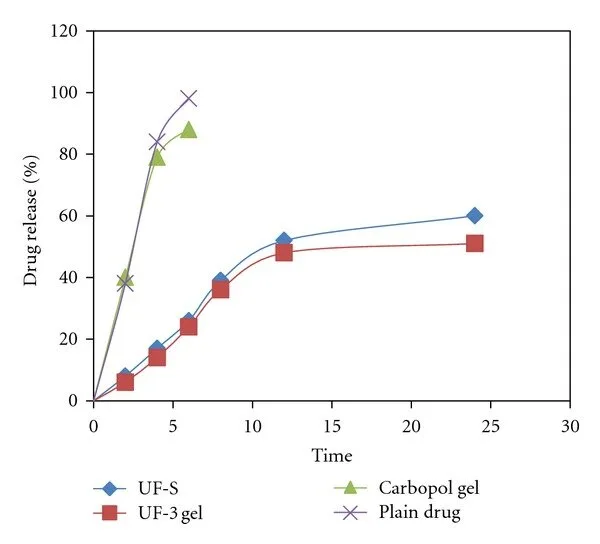

2.2 Drug Delivery Systems

Edible Coatings: Encapsulates pills or topical medications, ensuring controlled release.

Transdermal Patches: Serves as a backing layer for patches, compatible with sensitive skin.

2.3 Wound Dressing & Surgical Barriers

Moisture Control: Cellulose film’s semi-permeability allows oxygen exchange while preventing bacterial contamination, ideal for burn dressings (e.g., temporary skin substitutes).

Surgical Drapes: Used as sterile barriers during operations due to its lint-free and hypoallergenic nature.

3. Market Outlook

With the promotion of regulation and cost reduction, the global medical cellulose film market is expected to grow at a rate of more than 10% (2025-2030)

4. Conclusion

Cellulose film’s versatility, safety, and sustainability position it as a cornerstone material in modern medicine. As technology advances, its applications will expand, further bridging the gap between clinical efficacy and environmental responsibility.

5. About Kede New Material

Kede New Material Materials delivers advanced biodegradable medical packaging films engineered for exceptional durability, moisture barrier protection, and sterilization compatibility. Our certified eco-adhesive systems rigorously comply with global regulatory requirements, enabling healthcare organizations to effectively reduce their carbon footprint while uncompromisingly maintaining product quality and safety standards.

Through the integration of cutting-edge materials science and sustainable manufacturing processes, Kede New Material establishes the benchmark for environmentally responsible medical packaging solutions. Our specialized expertise provides hospitals, pharmaceutical companies, and medical device manufacturers with high-performance biodegradable packaging options, advancing the industry toward a more sustainable future.