Sustainable Packaging Materials: PLA, PBAT, PHA, and Cellulose Film

Introduction

Sustainable packaging minimizes environmental impact throughout a product’s lifecycle—from production to disposal. It goes beyond “eco-friendly materials,” covering design, material selection, manufacturing, usage, and end-of-life management.

The 4R principle—Reduce, Reuse, Recycle, and Recover/Compostable—is often referenced to guide packaging decisions. It is not mandatory, but helps businesses choose the right strategies, such as reducing material use, designing reusable packaging, selecting recyclable materials, or using biodegradable/compostable materials.

Types of Sustainable Packaging

- Recyclable Materials: Paper, cardboard, certain plastics, glass, metals

- Reusable Materials: Durable containers and packaging systems

- Plant-Based Materials: Derived from renewable plants

- Biodegradable Materials: Can be decomposed by microorganisms

- Compostable Materials: Fully break down under specific conditions into CO₂, water, and organic matter

All compostable materials are biodegradable, but not all biodegradable materials are compostable. Compostable materials meet a higher environmental standard and can decompose completely in home or industrial composting.

Learn more: Compostable vs. Biodegradable Materials

Material Overview

1. PLA (Polylactic Acid): Bio-based Option for Industrial Composting

Material Properties

- Source: Renewable plant resources such as corn starch and sugarcane

- Transparency: Excellent, similar to conventional polystyrene

- Mechanical Properties: High rigidity but relatively brittle

- Compostability: Fully decomposable under industrial composting conditions (58°C or higher) into CO₂, water, and organic matter

Applications

- Rigid clear boxes

- Disposable tableware and cups

- 3D printing materials

- Food packaging films

Environmental Assessment

PLA is renewable, but it only decomposes effectively under industrial composting. In natural environments or home composting, decomposition is slow, limiting its overall environmental benefit.

2. PBAT: Flexible Synthetic Material

Material Properties

- Source: Mainly petroleum-based, with some bio-based versions under development

- Mechanical Properties: Excellent flexibility and elongation, similar to LDPE

- Processability: Excellent film-forming capability

Applications

- Compostable shopping bags

- Flexible packaging films

- Agricultural mulch films

- Blended with PLA to improve performance

Environmental Assessment

PBAT largely relies on petroleum and only decomposes effectively in industrial composting conditions, limiting its sustainability.

3. PHA: Ocean-Friendly Biopolymer

Material Properties

- Source: Natural polyester produced by bacterial fermentation of sugars or lipids

- Biocompatibility: 100% bio-based

- Full Environmental Degradation: Can degrade in soil, freshwater, and marine environments

- Mechanical Properties: Ranges from elastomeric to rigid materials

Applications

- Marine product packaging

- Agricultural films (soil-degradable)

- Medical sutures and implants

- High-end eco-friendly packaging

Environmental Assessment

PHA represents the highest environmental standard for biopolymers, certified for marine biodegradability (ASTM D7081). However, high production costs limit large-scale applications.

4. Cellulose Film: Natural Compostable Choice

Source and Production

- Raw Materials: 100% renewable cellulose from wood pulp or cotton linters

- Clean Process: Dissolution–casting–drying physical regeneration process

- No Chemical Additives: No petroleum-based monomers or chemical catalysts

Outstanding Environmental Performance

- Dual Composting Certification

- Home compostable: Fully decomposes under typical home composting conditions

- Industrial compostable: Meets EN 13432 and ASTM D6400 standards

- Complete degradation: Converts into CO₂, water, and organic matter without harmful residues

- Natural Anti-Static Properties

- Surface resistivity: 10⁷–10⁹ Ω (safe dissipation range)

- Static decay time: <1 second (vs. ~300 seconds for conventional plastics)

- No additives required, long-lasting performance

Applications

- Fireworks packaging: Link

- Fruits & vegetables: Link

- Medical packaging: Link

- Automotive packaging: Link

- Sausage casings: Link

Learn more: Natural Cellulose Film

Material Performance Comparison

| Material | Source | Applications | Advantages | Limitations |

|---|---|---|---|---|

| PLA | Corn, sugarcane | Rigid boxes, disposable tableware, food films | High transparency, food safe | Industrial composting only, slow home composting |

| PBAT | Petroleum (some bio-based) | Flexible packaging, agricultural films, PLA blends | Flexible, easy processing | Petroleum-dependent, limited sustainability |

| PHA | Bacterial fermentation | Marine packaging, medical & high-end packaging | Fully degradable in multiple environments | High cost, limited production scale |

| Cellulose Film | Wood pulp, cotton linters | Food, medical, electronics, anti-static applications | Compostable, transparent, anti-static, renewable | Higher cost than plastics |

Recommended Usage:

- Highest environmental standards: Cellulose film or PHA

- Electronics packaging: Cellulose film (natural anti-static, transparent, compostable)

- Cost-efficient large-scale applications: PLA or PLA + PBAT blends

- Marine safety requirements: PHA

- Flexible packaging needs: PBAT or cellulose film

Market Trends

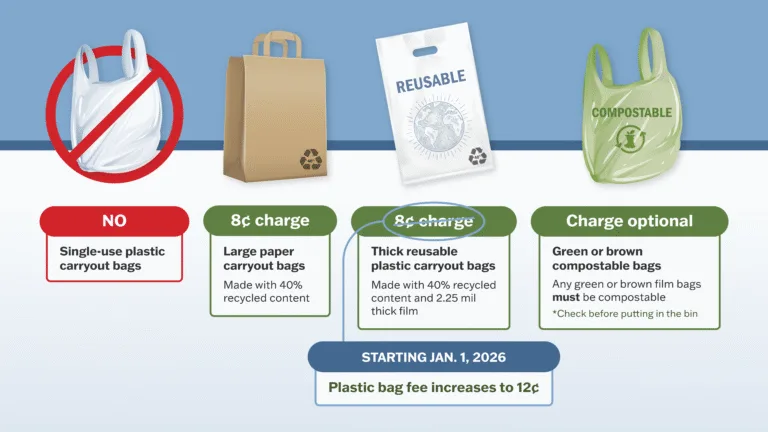

- Regulations: EU Single-Use Plastics Directive, PPWR; China’s upgraded plastic restrictions; stricter marine plastic controls in Japan & South Korea

- Technology: PHA costs decreasing; cellulose film functional improvements; bio-based PBAT maturing; composting and marine degradation standards improving

- Forecast: PLA & PBAT dominate 2025–2027; PHA high-end growth 2027–2030; cellulose-based materials expand post-2030

About Shaoxing KEDE New Material Co., Ltd.

Founded in 2006, KEDE is one of the top five global cellulose film manufacturers. We specialize in truly compostable natural cellulose films, providing high-standard eco-friendly packaging solutions worldwide.

Core Advantages:

- Nearly 20 years of industry experience, mastering regenerated cellulose technology

- ISO9001:2000 & ISO14001:2004 certified; compliant with EU food contact standards

- 100% natural origin, fully compostable at home & industrial scale, natural anti-static

- Product range: Clear & colored cellulose films, medical films, biodegradable tapes

- Custom services: Thickness, size, printing, functional modification

- Applications: Food, medical, electronics, fireworks, sausages, automotive

Contact Us:

- 📞 Phone: +86-575-85749268

- 📧 Email: kede@selofanfilm.com

- 💬 WhatsApp: +86 151 6756 6359 (Link)

- 🏭 Factory: No. 91 Qiu, Haitubinhai Industrial Zone, Keqiao District, Shaoxing, Zhejiang, China

- 🌐 Website: selofanfilm.com