Natural Cellulose Film: The Perfect Union of Static Protection and Sustainable Packaging

Permanent, inherent static dissipation—without additives or metal coatings—paired with true end‑of‑life sustainability.

Why static matters—and why traditional fixes fall short

In today’s digital world, static protection is mission‑critical. From sensitive electronic components to premium consumer goods, uncontrolled static can damage functionality and attract dust, compromising appearance. Traditional anti‑static packaging often relies on chemical additives or metal coatings that can wear off or complicate recycling. A new option—natural cellulose film—delivers smarter, permanent protection and a lighter environmental footprint.

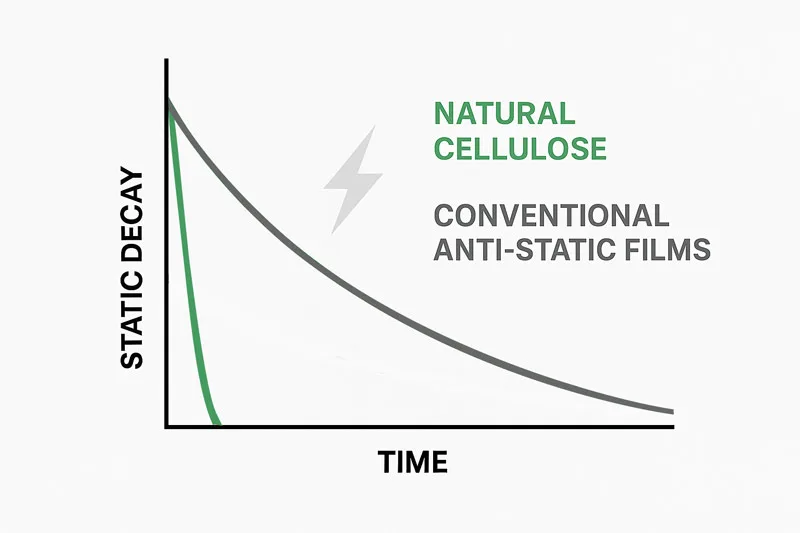

The secret to static dissipation: the data speaks

Unlike plastics that need coatings or migrating additives, the anti‑static properties of natural cellulose film are inherent to its structure and do not diminish over time.

- Stable intrinsic surface resistivity: 107–109 Ω, a safe dissipative range that bleeds charge off the surface in a controlled way.

- Superior static dissipation: tribocharge ~ 0.3 kV; static decay time < 1 s—far better than typical plastics (up to 12.5 kV, decay ~ ≥ 300 s).

- Permanent No loss of performance through friction or age; no additive bloom.

Plain‑language takeaway: these values mean the film safely dissipates charge before sparks occur or dust is attracted.

Natural Cellulose Film vs. traditional anti‑static packaging

| Material | Pros | Cons | Sustainability |

|---|---|---|---|

| Pink anti‑static bags | Low cost; basic static inhibition. | Function relies on additives that can wear off; no true shielding; limited clarity over time. | Mostly non‑recyclable plastics |

| Silver / metallized shielding bags | Strong external field shielding (Faraday cage). | Opaque; higher cost; multi‑layer, hard to recycle. | Multi‑material waste |

| Conductive foam / sponges | Rapid conduction to ground; cushioning for IC pins. | Bulky; opaque; limited to transport/production uses. | Non‑biodegradable |

| Natural cellulose film | Permanent dissipative performance; crystal‑clear display. | Not intended as full EM shielding (use case dependent). | Compostable end‑of‑life |

Compostable: a promise beyond “eco‑friendly”

Compostable means the film breaks down in controlled composting within a defined timeframe, returning to soil as nutrient‑rich humus—without toxic residues. This goes further than generic “biodegradable,” which merely means microbes can break it down at some point, often with no time limit and no assurance about microplastics or toxins.

- All compostable products are biodegradable, but not all biodegradable products are compostable.

- “Biodegradable” isn’t consistently regulated: there’s usually no time limit or toxicity testing; any material will biodegrade eventually (even centuries later).

- Cellulose film is plant‑based and compostable—degrading into CO₂, water, and biomass, not persistent microplastics.

Where cellulose film shines

Consumer electronics accessories

Earbuds, cables, flash drives. Dissipative surface prevents dust attraction; high clarity elevates retail display; compostable end‑of‑life strengthens brand sustainability claims.

Precision optics & medical

Lenses, filters, diagnostic devices. Even tiny static‑induced dust impacts performance. Inherent dissipation keeps surfaces clean until use.

Specialized industrial materials

Fine powders or granules prone to clumping. Dissipative packaging promotes smooth flow and easy dispensing, improving efficiency.

Ready to pair static safety with sustainability?

Ask us about rolls, sheets, tinted and coated grades, and tape‑grade cellulose film with enhanced tensile properties.